Paul Barker wrote:Alex Kitic wrote:

Besides the possibility to blow the electronic transformer by adding capacity, I am even more concerned with the possibility that this might raise the voltage on the heaters.

No fear of either. Quite a few of us have walked this way before.

those two fears are unfounded.

What else can I say, but Victory!

I opened the boxes and analyzed the circuitry, found the bridge (1N4007) diodes, checked the polarity... and found as well the 156nF/400V cap inside! The wires are basically paralleling the outside capacitor (330uF/400V) with the small cap inside.

I did it first with one... to be able to compare the channels. I was literally floored when there was absolutely nothing on the tweaked channel! While the normal channel had some hum/buzz (not much, but quite audible near the speaker) the tweaked channel has nothing... well, maybe we could trace something on the scope, but all that can be heard is some tube noise from the tweeter (with one ear stuck in the tweeter). I had to call my daughter to verify whether there is something else to be heard that I do not hear... but she does not hear it either.

Procedure repeated with the other unit, boxes closed - just two wires sticking out, connected to the caps. Total silence at power-up, incredible... I had to play some music to be sure it is working.

Thus, VICTORY - no hum, no noise... combined with AC simplicity and, what is most important in my opinion, the fact that the whole filament is at the same potential (which is the main issue with DC heating, regardless of type - current regulated, voltage regulated, battery operated...).

Now for the "bad news".

I had the impression that the tweaked channel tube was slightly brighter lit (it is difficult to tell exactly, since the two tubes are, unfortunately, not physically identical, one is an RCA the other a Haltron). Besides, it started faster than the normal channel. It is thus my impression that the tweak actually affects the output voltage...

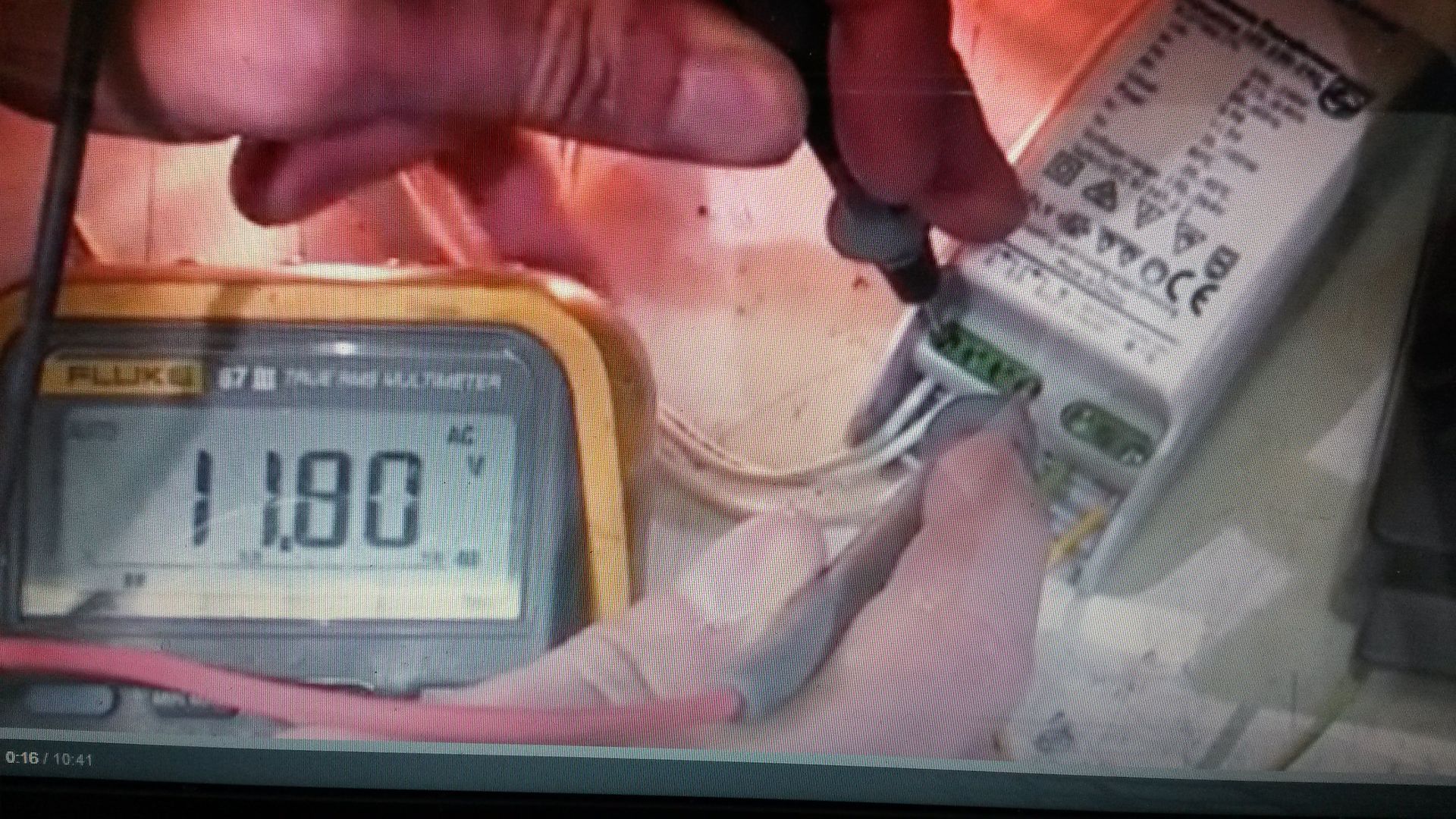

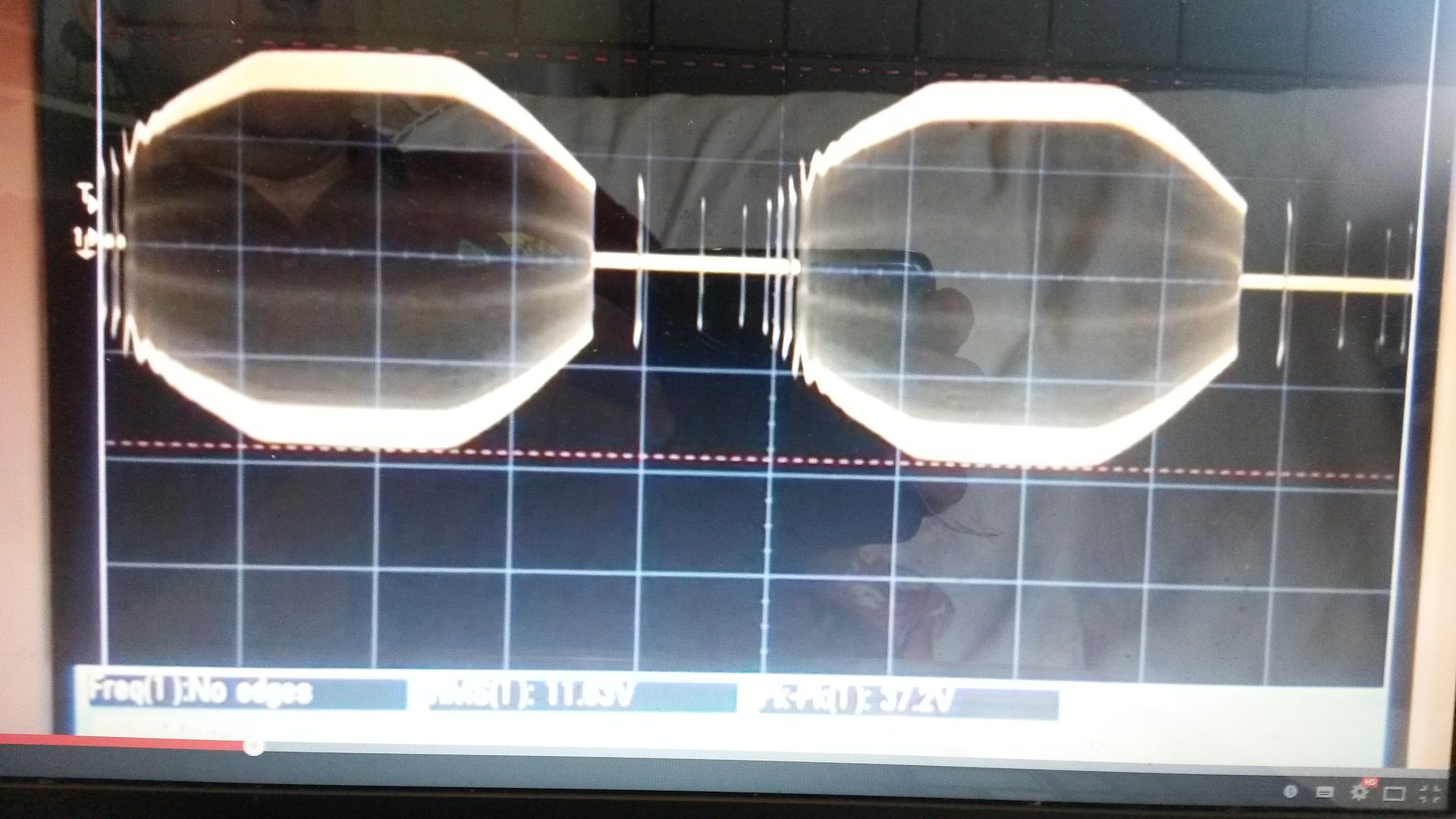

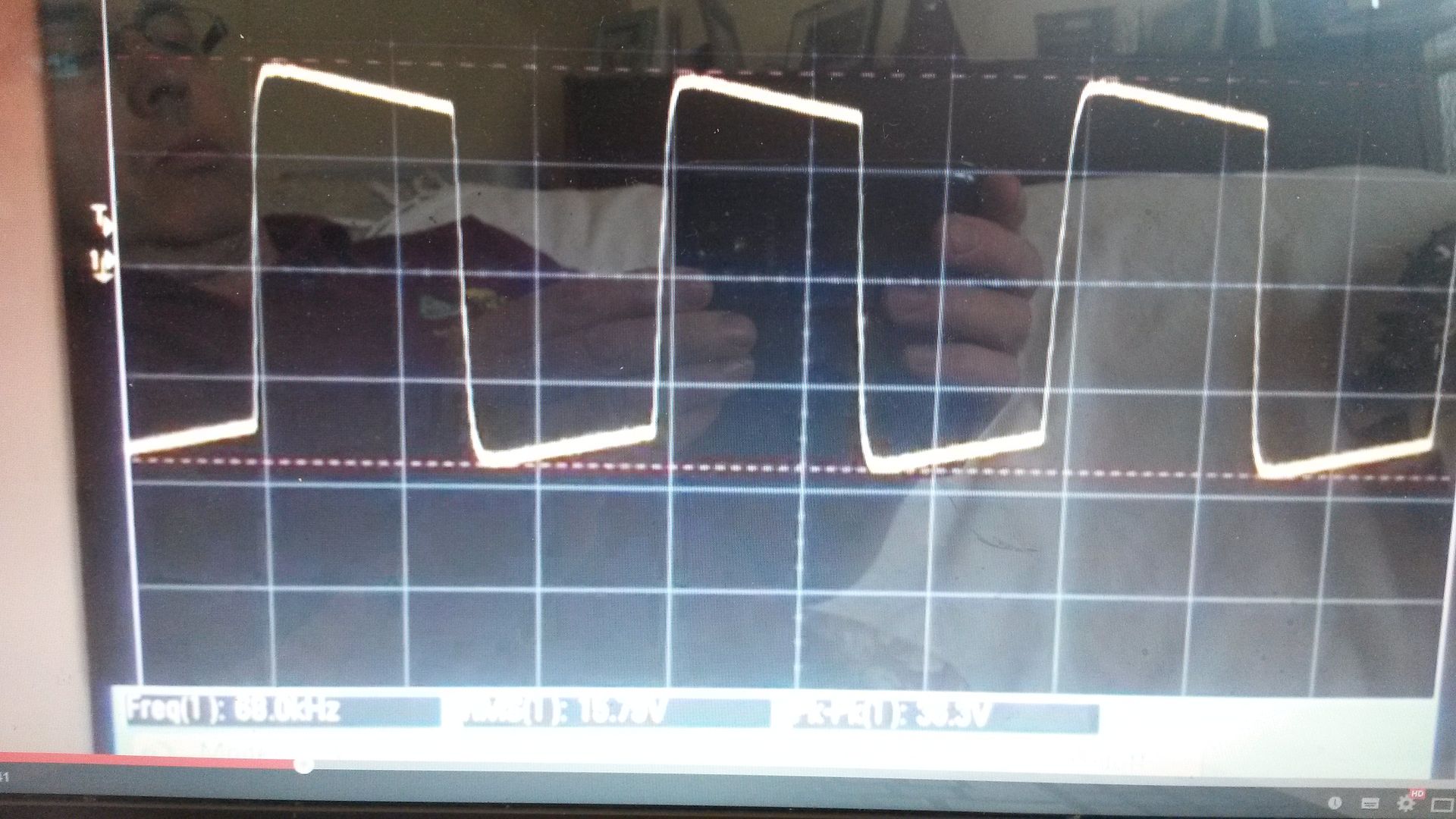

Since I cannot measure high frequency AC voltage, I did some informative measurements for comparison sake. The normal channel shows (both did without the tweak) a reading of 28-29V AC, while the tweaked channel shows 43V. The drop across a 0.15 ohm resistor is almost identical on all 4 resistors, at 0.87V. It is my impression that the voltage has risen at least 0.5-0.7V AC after the tweak.

To feel safer, I quickly found some resistors and added 0.11 ohms on each channel. The drop across this resistor has a reading slightly lower than the 0.15 ohm resistors... and the resulting voltage is shown as 31V. From that I deduct that after adding the 0.11 resistor the heater voltage is again "normal". At 5A current draw, the additional resistor should be dropping some 0.55V... and judging by the light of the tubes, I have the impression that it is correct (like before).

The voltage increase could probably be calculated, and I believe it is caused by the decrease in ripple (effectively, decreasing ripple means elevating the RMS DC voltage). If the resulting AC increase is a percentage related to the increase in DC voltage, that's easy to counter with additional resistors. Besides calculating, it is quite easy to measure the DC voltage at the cap wires with and without the cap...

But there must be a means to measure high frequency AC voltage, without spending 1000 USD for a voltmeter?!

Paul Barker wrote:Alex Kitic wrote:I will look again into the cancellation schematics to see how to adapt the cathode resistor version to electronic transformer heating... wouldn't it be more logical to inject part of the noise directly (across a cap)?

You'd have to ask Stephie Bench any questions, but I don't know if Stephie is accessible these days.

I wouldn't try to alter anything of Stephie's. I am too dumb. If you think you are cleverer be my guest.

I checked the explanation Steve gave (I admit never reading it before) and understood - this is not plain AC injection, but rather the injection of the fundamental and subsequent harmonics, filtered in a precise way.

I would not modify anything there... but it does not seem to be applicable to the HF AC heating method. Most importantly, there is absolutely no need to get that far, since adding a cap does the trick.

What puzzles me now is - have you had such extremely good results with HF AC (no hum, no buzz, nothing!) in your experiments? Maybe the tweak decreases hum/buzz/noise to a point where it becomes inaudible with the RH circuitry (as commented before, hum from direct heated tubes on normal AC mains is a lot lower than with a no-feedback circuitry, from almost inaudible to negligible)...